Production of recon tobacco for cut rag tobacco

The first Recon tobacco (created by the press method) which is processed in DCC.

Low cost of production. As a consequence, the low price.

90% tobacco. Minimal binders.

Request a Sample/Quote

*The information you provide will not be shared with third parties. We do not do automated mailings. We do not send you SPAM. Your contact information is only used to communicate with you about our products.

“

Homogenization (from Greek ὁμογενής - uniform) - a technological process in which substances in a fluid medium are evenly distributed throughout the volume of said medium. Regarding the tobacco industry, the outcome of the homogenization process yields a product with various designations: Homogenized Tobacco Leaf (HTL), homogenized tobacco, homogenized tobacco paper, homogenized tobacco sheet.

Homogenized or Reconstituted tobacco?

Both products share a common objective - reducing the production cost of tobacco goods and their detrimental impact on human health. Differences arise in the manufacturing method, with all the ensuing advantages and drawbacks.

The two primary techniques for creating homogenized tobacco globally are paper recon and slurry recon. These methods are prevalent but present significant obstacles for manufacturers concerning flavor, drying, and material tensile strength. They demand substantial space and energy resources, and they do not optimally preserve the product's quality.

Below is a comparison chart of the characteristics of Homogenized Tobacco and Reconstituted Tobacco:

The two primary techniques for creating homogenized tobacco globally are paper recon and slurry recon. These methods are prevalent but present significant obstacles for manufacturers concerning flavor, drying, and material tensile strength. They demand substantial space and energy resources, and they do not optimally preserve the product's quality.

Below is a comparison chart of the characteristics of Homogenized Tobacco and Reconstituted Tobacco:

Feature

Homogenized Tobacco

Our reconstituted tobacco

Method of production

Paper making, Slurry

Pressing

Usage

Usage Used to substitute cigarette paper and tobacco leaf binder on cigars.

Usually used in cigarettes, cigars as a filler or in combination with other types of tobacco.

Form of delivery

A roll of HTL tobacco

Cut rag or sheets 100*100 мм

Cost

Cost Relatively more expensive because of energy-intensive production

Relatively lower cost due to the perfection of the technology.

Energy consumption

High

Low

Environmental Impact

Significant because of the use of large amounts of water in the technological process.

No negative impact on the environment.

Resistance (kg/m)

35-70

50-60

Filling Power (cc/gr)

35-65

55-65

Aroma

Good

Excellent

Nicotine Content

Medium

High

Grams (sq. meter)

110-180

150

About

- The Russian Tobacco Factory is globally recognized as a dependable and efficient supplier of recon tobacco, with a significant portion of our business devoted to managing B2B relationships. Buy wholesale recon tobacco directly from the factory.

- Recon tobacco leaf is crucial in cigarette production and can be derived from either the customer's byproducts or specially sourced tobaccos.

- We provide a variety of standard recon tobacco leaf options, such as Ready-to-Use, American Blend/Virginia, and Oriental/Burley, which are available for immediate use or for sale with minimal wait time.

- Our Recon Tobacco offers notable cost benefits for blending, allowing manufacturers to create competitive cigarette products by combining recon and virgin tobacco in various ratios. This is particularly important in emerging markets, where a competitive edge in pricing and quality is vital for success and market share growth.

- Traditional recon tobacco sheet production methods involve a high glycerin-to-water ratio of up to 95% during processing. In contrast, our approach yields tobacco materials with significantly lower moisture content (20-40%), resulting in faster drying times and reduced nicotine and flavor loss. The Russian Tobacco Factory also minimizes binder usage, leading to a higher tobacco content of up to 90% and a reduced impact on flavor during combustion.

- We have the expertise to produce top-quality recon tobacco suitable for American and English/Canadian blends. These products can be integrated into our existing blends or tailored for use in your blend. We can also supply recon tobacco in its original form, customized to meet your specific requirements.

- The low moisture content of recon tobacco positively impacts environmental sustainability, as shorter drying times and decreased energy consumption result in lower production costs compared to competitors.

- Our tobacco slurry features a solid consistency, unlike conventional recon tobacco production systems, making it easy to roll uniformly and control thickness using rollers. This consistency in rolling contributes to uniformity in subsequent processes and helps maintain key product attributes, such as nicotine content, within the desired range.

- We are more accessible than you might think. With extensive experience in customs operations and the B2B tobacco business, we welcome you to visit and witness the bears playing the balalaika.

Diving into the history of Homogenized Tobacco

The problem of preserving valuable tobacco leaves has always been a pressing issue for manufacturers. Saving around 30% of tobacco lost by the tobacco industry on its way from the agricultural field to the finished pack of cigarettes was an important task. Only a company with frugality ingrained in its DNA from its inception could solve this problem.

It is a well-known fact that at RJ Reynolds, for a worker to get a new pencil, they had to return the stub of the old pencil. In the 1930s, RJ Reynolds, under the management of CEO Bowman Gray, achieved success.

Here is how this moment is described in the book "Barbarians at the Gate" (1989, ISBN 0-06-016172-8):

"Ingenuity: The company developed a way to recycle scraps and stems of tobacco to greatly increase the usable amount of each leaf—and greatly increase profits. "Reconstituted tobacco," as it was called, was considered classic Reynolds a blend of its manufacturing know-how and its waste-not, want-not culture"

Over the following decades, RJ Reynolds managed to win the competitive battle and maintain low prices for its products by utilizing Homogenized Tobacco.

As early as 1956, Time magazine reported that General Cigar claimed outstanding consumer acceptance for: General Cigar claims "fantastic consumer acceptance" for HTL, which is used in place of conventional "binder," the layer of tobacco (12% of the cigar) that is sandwiched be tween inside "filler" and outer "wrapper.".

Cigars were once considered an exclusive luxury, accessible mainly to wealthy individuals. HTL emerged as a solution to offer more affordable cigars, catering to a broader population seeking this sophisticated experience.

It is a well-known fact that at RJ Reynolds, for a worker to get a new pencil, they had to return the stub of the old pencil. In the 1930s, RJ Reynolds, under the management of CEO Bowman Gray, achieved success.

Here is how this moment is described in the book "Barbarians at the Gate" (1989, ISBN 0-06-016172-8):

"Ingenuity: The company developed a way to recycle scraps and stems of tobacco to greatly increase the usable amount of each leaf—and greatly increase profits. "Reconstituted tobacco," as it was called, was considered classic Reynolds a blend of its manufacturing know-how and its waste-not, want-not culture"

Over the following decades, RJ Reynolds managed to win the competitive battle and maintain low prices for its products by utilizing Homogenized Tobacco.

As early as 1956, Time magazine reported that General Cigar claimed outstanding consumer acceptance for: General Cigar claims "fantastic consumer acceptance" for HTL, which is used in place of conventional "binder," the layer of tobacco (12% of the cigar) that is sandwiched be tween inside "filler" and outer "wrapper.".

Cigars were once considered an exclusive luxury, accessible mainly to wealthy individuals. HTL emerged as a solution to offer more affordable cigars, catering to a broader population seeking this sophisticated experience.

What is Homogenized Tobacco Leaf (HTL)?

The Homogenized Tobacco Leaf (HTL) is a tobacco-derived product manufactured using the papermaking technique. This process is used to create a tobacco leaf that is more uniform in texture and taste than traditional tobacco leaves. This method converts tobacco leaves into functional paper sheets that retain the authentic flavor and scent of natural tobacco. Within the tobacco sector, HTL serves as an alternative to traditional cigarette paper and tobacco leaf binders in cigars.

Selection of HTL products includes the HTL Wrapper, designed for the exterior layer of cigars or small cigars, and the HTL Binder, which serves as the inner layer for holding the tobacco filler in place.

The binder and wrapper, which are the inner and outer covers of machine-made cigars, often use HTL (Homogenized Tobacco Leaf) as it shows greater strength and consistency compared to using whole tobacco leaves.

In cigar production, HTL can be utilized as either a wrapper or binder. Ideally, it serves as a binder situated beneath a natural leaf wrapper (like the La Aurora Principes Corona Natural). The binder accounts for just 12% of a complete cigar, resulting in a finished appearance similar to that of a handmade cigar. This means that only one of the three components is made from homogenized tobacco, while the rest consist of 100% natural tobacco leaf.

Selection of HTL products includes the HTL Wrapper, designed for the exterior layer of cigars or small cigars, and the HTL Binder, which serves as the inner layer for holding the tobacco filler in place.

The binder and wrapper, which are the inner and outer covers of machine-made cigars, often use HTL (Homogenized Tobacco Leaf) as it shows greater strength and consistency compared to using whole tobacco leaves.

In cigar production, HTL can be utilized as either a wrapper or binder. Ideally, it serves as a binder situated beneath a natural leaf wrapper (like the La Aurora Principes Corona Natural). The binder accounts for just 12% of a complete cigar, resulting in a finished appearance similar to that of a handmade cigar. This means that only one of the three components is made from homogenized tobacco, while the rest consist of 100% natural tobacco leaf.

How has the world of cigars changed with the advent of Homogenized Tobacco Leaf (HTL)?

The development of homogenized tobacco leaf (HTL) has caused a major shake-up in the cigar industry.

Many contemporary cigar factories embrace the principle of waste minimization, exemplified by the ingenious repurposing of fragmented tobacco in the fabrication of machine-made cigars.

Industrial facilities craft machine-made cigars by employing specialized rolling contraptions to merge the organic cigar sheath, Homogenized Tobacco Leaf (HTL) binder, and authentic filling, resulting in an exquisite, uniform product. In contrast to handmade cigars, machine-crafted variants exhibit remarkable consistency in filling quantity and dispersion, enhancing draw performance and promoting a more even combustion.

To curtail expenses, some producers elect to use a Homogenized Tobacco Leaf (HTL) covering as opposed to its natural equal. Among these, the majority prefer a simple HTL sheath combined with authentic filling, devoid of a binder. The sheath's influence on the composite flavor profile of a cigar can span from 20 to 50 percent, contingent upon the cigar's dimensions.

Procuring a high-quality machine-manufactured cigar with truncated filling offers a dependable method for indulging in a cost-effective smoking experience.

Adopting a restructured tobacco sheath and binder (or the sheath without binder) signifies a notable departure from the 100% pure tobacco intrinsic to a premium handmade cigar. Illustrative instances comprise Dutch Masters, Century Sam, White Owl, and Phillies.

These cigars are discerned by their smooth exterior, attributed to the absence of veins and undulations found on organic tobacco foliage. Owing to their modest price and the parchment-like nature of the Homogenized Tobacco Leaf (HTL) covering, these cigars garner popularity among cannabis enthusiasts, who often dissect them, extract the filling, and encase cannabis within to forge a "blunt."

Innovations in machine-made techniques, incorporating the integration of truncated filling and HTL binding, have revealed a universe of novel opportunities for savoring cigars at exceptional value. While an elite, hand-rolled cigar remains the ultimate standard, it is crucial not to undervalue the enjoyment derived from a superior machine-crafted cigar.

Many contemporary cigar factories embrace the principle of waste minimization, exemplified by the ingenious repurposing of fragmented tobacco in the fabrication of machine-made cigars.

Industrial facilities craft machine-made cigars by employing specialized rolling contraptions to merge the organic cigar sheath, Homogenized Tobacco Leaf (HTL) binder, and authentic filling, resulting in an exquisite, uniform product. In contrast to handmade cigars, machine-crafted variants exhibit remarkable consistency in filling quantity and dispersion, enhancing draw performance and promoting a more even combustion.

To curtail expenses, some producers elect to use a Homogenized Tobacco Leaf (HTL) covering as opposed to its natural equal. Among these, the majority prefer a simple HTL sheath combined with authentic filling, devoid of a binder. The sheath's influence on the composite flavor profile of a cigar can span from 20 to 50 percent, contingent upon the cigar's dimensions.

Procuring a high-quality machine-manufactured cigar with truncated filling offers a dependable method for indulging in a cost-effective smoking experience.

Adopting a restructured tobacco sheath and binder (or the sheath without binder) signifies a notable departure from the 100% pure tobacco intrinsic to a premium handmade cigar. Illustrative instances comprise Dutch Masters, Century Sam, White Owl, and Phillies.

These cigars are discerned by their smooth exterior, attributed to the absence of veins and undulations found on organic tobacco foliage. Owing to their modest price and the parchment-like nature of the Homogenized Tobacco Leaf (HTL) covering, these cigars garner popularity among cannabis enthusiasts, who often dissect them, extract the filling, and encase cannabis within to forge a "blunt."

Innovations in machine-made techniques, incorporating the integration of truncated filling and HTL binding, have revealed a universe of novel opportunities for savoring cigars at exceptional value. While an elite, hand-rolled cigar remains the ultimate standard, it is crucial not to undervalue the enjoyment derived from a superior machine-crafted cigar.

How homogenized tobacco leaf is made?

The production process typically involves mixing the tobacco scraps and dust with water to form a slurry, adding the binding agents and other ingredients, and then forming the mixture into sheets using a paper-making process. These sheets are then dried, cut into the desired shape.

The process can be broken down into the following stages:

Step 1: Preparing the Raw Materials

First things first, the raw tobacco leaves are carefully selected and sorted based on their quality and characteristics. This stage is intended to sift and eliminate any non-tobacco materials and large particles. It includes the extraction of metal fragments.

Step 2: Pulping the Tobacco

Next, the leaves are ground into a fine pulp using a combination of mechanical and chemical processes.

In more specific terms, the tobacco dust possesses an average particle size ranging from approximately 60 mesh to 400 mesh. This results in homogenized tobacco sheets with about 75% tobacco content, exhibiting enhanced quality and durability. The smaller particle size of the tobacco dust enables a higher solid content in the slurry without increasing its viscosity. This heightened solid content lowers the drying load of the cast sheet, subsequently allowing for a faster production rate.

This pulp is then mixed with water and other additives to create a homogenous mixture, which forms the base for the homogenized tobacco leaf.

Step 3: Paper Making

This is where the "paper method" comes into play. The fiber portion and the soluble portion are separated. The mixture of tobacco pulp is passed through a series of rollers and dryers, which press and dry the tobacco pulp into a thin, uniform layer. The fibrous component proceeds to the paper-making process, where it is shaped into a base sheet. The soluble material is purified and then concentrated through evaporation. Afterward, the formed sheet and the extracted soluble are combined once more.

The composition of PM (Pulp and Mechanical Refining) for homogenized tobacco involves several pieces of equipment.

The process can be broken down into the following stages:

Step 1: Preparing the Raw Materials

First things first, the raw tobacco leaves are carefully selected and sorted based on their quality and characteristics. This stage is intended to sift and eliminate any non-tobacco materials and large particles. It includes the extraction of metal fragments.

Step 2: Pulping the Tobacco

Next, the leaves are ground into a fine pulp using a combination of mechanical and chemical processes.

In more specific terms, the tobacco dust possesses an average particle size ranging from approximately 60 mesh to 400 mesh. This results in homogenized tobacco sheets with about 75% tobacco content, exhibiting enhanced quality and durability. The smaller particle size of the tobacco dust enables a higher solid content in the slurry without increasing its viscosity. This heightened solid content lowers the drying load of the cast sheet, subsequently allowing for a faster production rate.

This pulp is then mixed with water and other additives to create a homogenous mixture, which forms the base for the homogenized tobacco leaf.

Step 3: Paper Making

This is where the "paper method" comes into play. The fiber portion and the soluble portion are separated. The mixture of tobacco pulp is passed through a series of rollers and dryers, which press and dry the tobacco pulp into a thin, uniform layer. The fibrous component proceeds to the paper-making process, where it is shaped into a base sheet. The soluble material is purified and then concentrated through evaporation. Afterward, the formed sheet and the extracted soluble are combined once more.

The composition of PM (Pulp and Mechanical Refining) for homogenized tobacco involves several pieces of equipment.

- The Headbox, which is of the pressurized type, is responsible for controlling the dilution of the slurry, ensuring that the right consistency is maintained throughout the process. It also has the capability to profile the dilution for optimal performance.

- The Fourdrinier wire, which is also known as a shaker, is a mesh-like material that helps to form a uniform sheet from the slurry.

- The Press section is where the slurry is pressed and dewatered to remove excess water.

- The Dryer section is where the slurry is dried and transformed into a solid form.

- The Size press is used to improve the uniformity and strength of the homogenized tobacco sheet.

- The Air contactless dryer is used to dry the homogenized tobacco without coming into contact with air, preserving the quality of the product and avoiding any contamination.

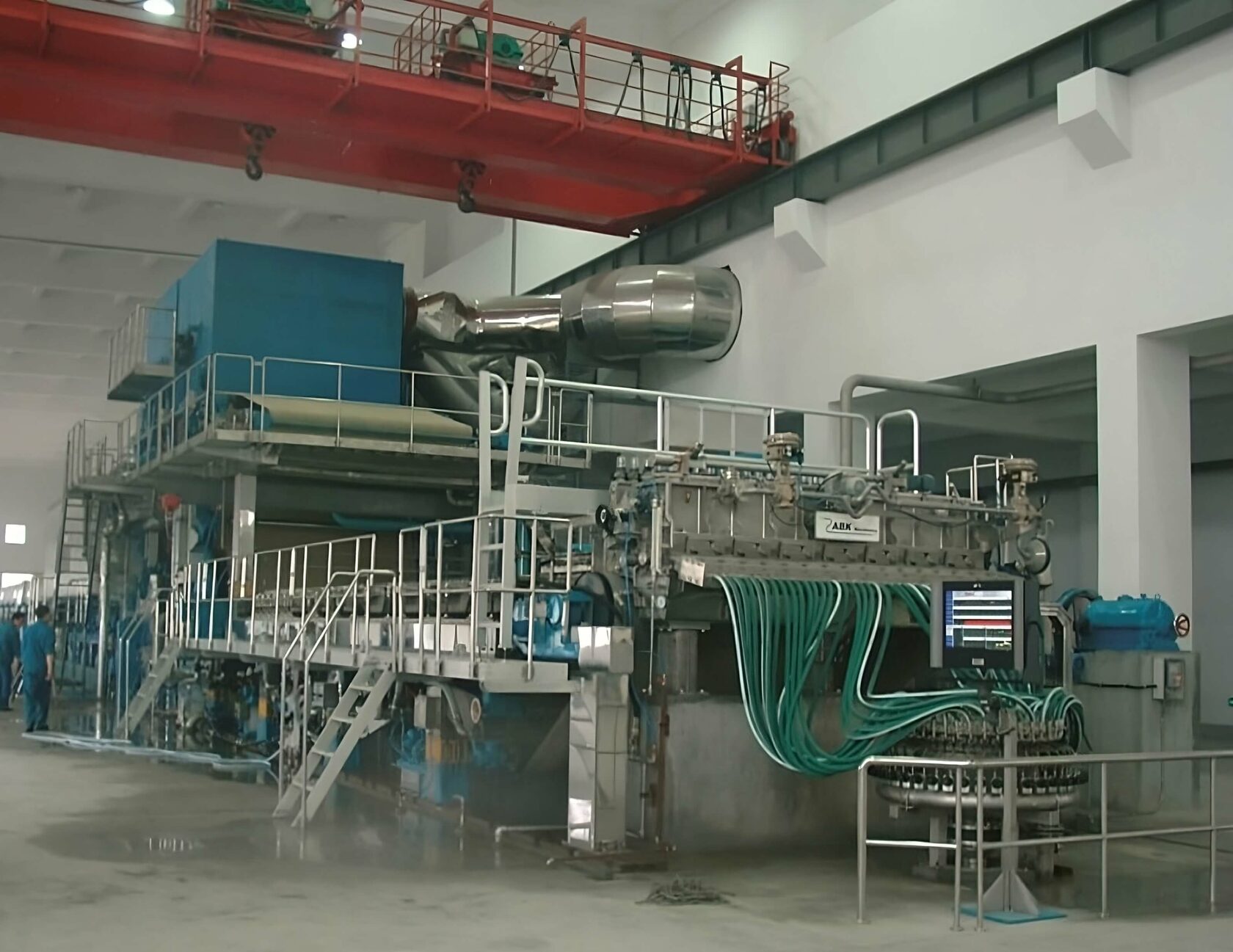

Yankee cylinder machine for the production of homogenized tobacco leaf

Step 4: Cutting and Packing

After the tobacco leaf is dried and cooled, it is cut into the desired size. The sheet is dried and trimmed into appropriate shapes for use by cigarette and cigar manufacturers. Commodity type of homogenized tobacco - continuous rolls of the desired width.

After the tobacco leaf is dried and cooled, it is cut into the desired size. The sheet is dried and trimmed into appropriate shapes for use by cigarette and cigar manufacturers. Commodity type of homogenized tobacco - continuous rolls of the desired width.

What materials are used to produce homogenized tobacco leaf?

The primary materials used in the production of homogenized tobacco leaf are:

- Water: Water is used to create a slurry with the tobacco scraps and dust, which allows for easier processing and manipulation of the tobacco material. Water is the basis of the entire homogenization process.

- Tobacco scraps and dust: These are leftover materials from the processing of whole tobacco leaves. They can include stems, small broken leaf pieces, and tobacco dust. These scraps are collected and used as the main ingredient in the production of HTL.

- Binding agents: In order to form the tobacco into a sheet, binding agents are added to the tobacco slurry. Common binding agents used in HTL production include cellulose fibers (from wood pulp or other plant sources), food-grade starch, and pectin

- Fillers: Fillers may be added to the slurry to improve the texture, appearance, or burning characteristics of the HTL. Common fillers include calcium carbonate and magnesium carbonate.

- Flavorings and additives: To enhance the taste and aroma of the final product, flavorings and additives are often included in the HTL production process. These can include natural tobacco extracts, sugars, humectants (such as glycerol or propylene glycol), and various other flavorings.

- Preservatives: To increase the shelf life of the finished product, preservatives may be added to the slurry. Common preservatives include sodium benzoate and potassium sorbate.

Benefits of homogenized tobacco leaf

Homogenized tobacco leaf offers several benefits over traditional tobacco leaves. The homogenization process helps to standardize the product's quality and characteristics. Here are some of the benefits:

- Consistency: HTL ensures that every tobacco leaf is uniform in texture and taste, which results in a more consistent smoking experience.

- Uniformity: Homogenized tobacco has a consistent composition, appearance, and texture due to the blending and processing of various tobacco components.

- Homogenized tobacco sheets: The processed tobacco is formed into sheets that can be cut to the desired size and shape for various applications, such as cigarette paper or wrappers for cigars.

- Improved combustion: The uniform nature of the tobacco allows for a more consistent burn, which can result in a smoother smoking experience.

- Enhanced flavor: Flavor additives or casings can be applied more evenly to the homogenized tobacco, providing a more consistent taste.

- Aroma: HTL can help enhance the aroma of tobacco leaves, which can improve the overall smoking experience.

- Lower cost: Homogenized tobacco is often cheaper to produce than traditional tobacco products because it utilizes tobacco waste materials.

- Reduced tar and nicotine content: The manufacturing process can reduce the levels of tar and nicotine in the final product, as these substances can be more precisely controlled during production.

- Greater control over product characteristics: Homogenized tobacco allows manufacturers to more easily control and modify various aspects of the tobacco, such as flavor, strength, and burn rate.

- Environmental considerations: The use of tobacco waste materials in homogenized tobacco production can help reduce overall waste and promote sustainability in the tobacco industry.

- Standardized quality: Homogenized tobacco offers a more consistent quality, which can be advantageous for large-scale production and consumer expectations.

Specifications for homogenized tobacco

Homogenized tobacco is manufactured with specific parameters in mind to ensure a consistent and quality product. Here are some common specifications for homogenized tobacco:

- Tobacco blend: The blend of tobacco varieties used in the homogenized product is specified to create a consistent flavor and smoking experience. These blends may include different types of tobacco such as Virginia, Burley, or Oriental.

- Moisture content: The moisture content in homogenized tobacco is controlled to ensure proper combustion and to maintain freshness. It is usually maintained within a range of 12-18%.

- Sheet thickness: The thickness of the homogenized tobacco sheets is specified to suit the intended application, such as cigarette paper or cigar wrappers. This can range from very thin sheets for cigarettes to thicker sheets for cigars.

- Sheet dimensions: The size of the tobacco sheets can be tailored to the requirements of the specific tobacco product being manufactured, such as cigarette length or cigar ring gauge.

- Additives and flavorings: The type and amount of additives or flavorings used in homogenized tobacco are specified to achieve a consistent taste and aroma. These may include humectants, preservatives, flavors, and binders. Most often not disclosed by the manufacturer. This characteristic is hidden behind the article number.

- Tar and nicotine content: The tar and nicotine levels in homogenized tobacco are controlled to meet regulatory requirements and consumer preferences. Manufacturers often specify a target range for these components.

- Combustion properties: The burn rate and ash characteristics of homogenized tobacco are controlled to provide a consistent smoking experience. This may involve adjusting the tobacco blend, sheet thickness, or additives used.

- Physical properties: The tensile strength, porosity, and density of the reconstituted tobacco sheets are specified to ensure proper performance in the final tobacco product.

- Color: The color of homogenized tobacco is controlled to provide a consistent appearance across different batches and products. This can be achieved through the use of dyes or by adjusting the blend of tobacco components.

- Shelf life: The shelf life of homogenized tobacco is specified to ensure the product remains fresh and retains its desired characteristics during storage and transportation. This typically involves the use of appropriate packaging and storage conditions.

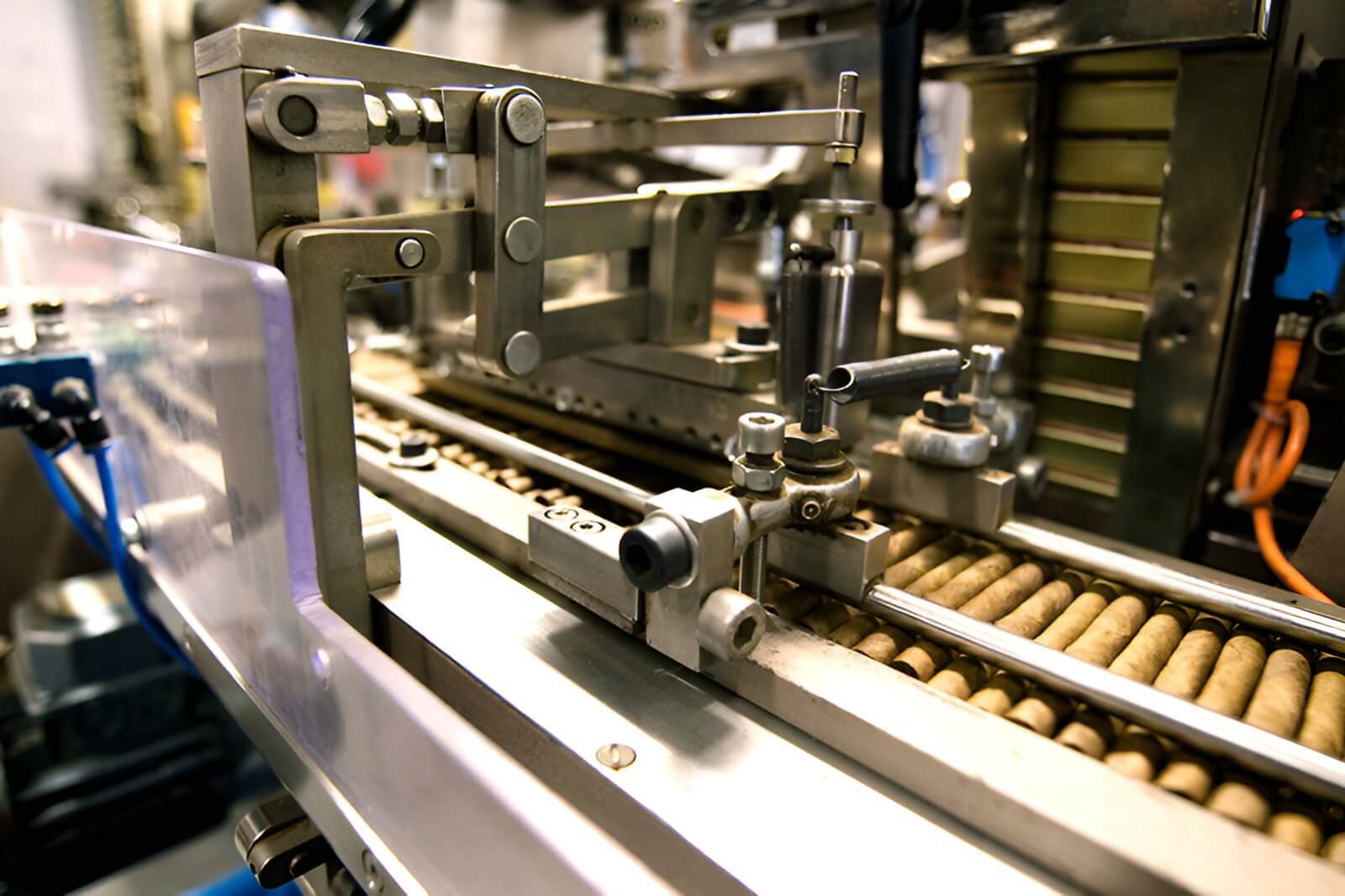

Machine rolling cigar

The majority of machine-produced cigars utilize homogenized tobacco leaf (HTL) for both the binder and often the wrapper. Nowadays, most cigars are manufactured using machines, with a typical machine requiring several workers to manage its various functions. One employee places tobacco leaves onto a conveyor belt between guide bars, adjusted to the desired cigar length, and the machine compacts the leaves to form the filler. Another worker positions the binder leaf (HTL) onto the binder mold, which is held in place by suction and cut to the appropriate size by the machine. The filler is then placed onto the binder mold, and the machine wraps the binder around it.

A third worker puts the wrapper leaf (HTL) on a wrapper mold, and the partially finished cigar is placed onto it. The machine proceeds to wrap the wrapper around the cigar. A fourth employee inspects the completed cigars and arranges them on trays. These finished cigars are then handed to an examiner who scrutinizes them for flaws and verifies their weight, size, shape, and the condition of the wrapper. The examiner may rectify any imperfections by patching wrappers or adjusting the shape of the cigar heads.

A third worker puts the wrapper leaf (HTL) on a wrapper mold, and the partially finished cigar is placed onto it. The machine proceeds to wrap the wrapper around the cigar. A fourth employee inspects the completed cigars and arranges them on trays. These finished cigars are then handed to an examiner who scrutinizes them for flaws and verifies their weight, size, shape, and the condition of the wrapper. The examiner may rectify any imperfections by patching wrappers or adjusting the shape of the cigar heads.

Frequently Asked Questions about Homogenized Tobacco Leaf

Here are some of the most frequently asked questions about homogenized tobacco leaf:

Yes, homogenized tobacco leaf is safe to smoke. The chemicals used in the homogenization process are generally regarded as safe and are used in many food and pharmaceutical products.

Yes, homogenized tobacco leaf contains nicotine. However, the amount of nicotine in homogenized tobacco leaf can vary depending on the type of tobacco used and the manufacturing process.

Homogenized tobacco leaf offers several benefits over traditional tobacco leaves, such as consistency, longevity, aroma, and reduced waste. However, whether it's better than traditional tobacco leaves is subjective and depends on personal preference.

One potential drawback is that the process can sometimes result in a slightly lower nicotine content, as some nicotine may be lost during the pulping and drying stages.

It is important to note that smoking cigars, regardless of whether they are made with Homogenized Tobacco Leaf (HTL) or natural tobacco leaves, carries health risks.

While the manufacturing process of HTL may involve the use of chemicals and binders, it is not clear whether cigars made with HTL present additional health risks compared to those made with natural tobacco leaves.

While the manufacturing process of HTL may involve the use of chemicals and binders, it is not clear whether cigars made with HTL present additional health risks compared to those made with natural tobacco leaves.

Homogenized Tobacco Leaf (HTL) affects the flavor, aroma, burn, and quality perception of cigars compared to those made with natural tobacco leaves. The homogenization process can result in a more uniform flavor and burn but may compromise the complexity, aroma, and overall perceived quality of the cigar. HTL cigars are often more affordable and common in machine-made cigars, which are generally considered to be of lesser quality than handmade cigars.

Consumers can identify cigars made with Homogenized Tobacco Leaf (HTL) by considering the following factors:

- Appearance: HTL cigars may have a more uniform appearance and texture than those made with natural leaves. The wrapper and binder made from HTL tend to be smoother and lack the natural veins or irregularities found in natural tobacco leaves.

- Price: Cigars made with HTL are generally more affordable than those made with natural leaves, as the production process is more cost-effective. If the price of a cigar is significantly lower than similar products, it might be an indication that it uses HTL.

- Brand and product information: Some manufacturers may indicate on the packaging or product description whether their cigars use HTL or natural tobacco leaves for the wrapper, binder, or filler. Researching the brand and specific product online can help you determine the materials used in the cigar's construction.

- Machine-made vs. handmade: HTL is commonly used in machine-made cigars, whereas handmade cigars usually feature natural tobacco leaves. If a cigar is labeled as machine-made, there is a higher likelihood that it incorporates HTL.